This month, BioBTX collected the € 80 million it needs for construction of its first commercial-sized factory. It will produce benzene, toluene and xylenes (BTX) from mixed plastic waste. A major step towards a circular plastics production.

BTX technology

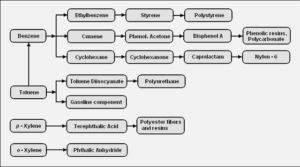

BioBTX’s technology implies that we can now produce many everyday products from waste. Products like insulating foams, coatings, PET bottles, batteries, and pharmaceuticals. A major opportunity for circular production models. BioBTX has successfully demonstrated its technology on its pilot plant in Groningen, the Netherlands.

The BioBTX project will be located at the PETRA Circular Chemicals Plant in Delfzijl. This plant will convert 20,000 tons of mixed plastic waste annually into renewable aromatics. They will replace fossil resources and recycle low-value plastic waste into high-value chemicals. If the pilot plant proves to be successful, the company intends to roll out the technology to chemical industry customers world-wide. The required €80 million is sourced from many interested parties both private and public.

From mixed plastics

The ICCP technology that the plants will use is a form of chemical recycling on the basis of pyrolysis, on the one hand. The material is heated in the absence of oxygen; this will crack it into smaller molecules. In this technology, subsequently the molecules are combined again into BTX. This combination of technologies is unique.

The big advantage of this procedure is that the company can make use of mixed plastics. This will do away with the need to separate the plastics on beforehand. Moreover, it is foreseeable that in the near future, companies will not be allowed anymore to export their plastic waste to countries outside the EU. Therefore we need a technology to process waste that cannot be recycled mechanically. This technology will allow carbon to stay within the chain for as long as possible. Because the BioBTX pathway involves pyrolysis, it does require a lot of energy. But still, this is less than the amount of energy required to produce these plastics from fossil oil.

Scaling up

With the €80 million investment, BioBTX intends to scale up its technology. Yearly capacity of the new factory will be 20,000 tons. Still a drop in the ocean, compared to chemical industry’s demand. Aromatics are a huge market with a value over $300bn/year. It is the origin of about 40% of all chemicals. But this market urgently needs cost-efficient circular alternatives. Therefore, the transition needs to start small in order to grow big.

This recycling technology will produce sustainable BTX at a commercial scale and at cost levels comparable to fossil BTX. Moreover, it will at the same time upgrade low-value plastic waste that would otherwise be incinerated. The new factory should be operational by the end of 2026. Ultimately, BioBTX intends to sell its technology to interested parties world-wide.

Interesting? Then also read:

BioBTX: Dutch School of Catalysis strikes again

Plastics recycling

Biobased aromatics: Europe leads the way