The Dutch agricultural sector has one major problem: an excess of manure production as a consequence of the large livestock population. Dutch livestock farming depends on major imports of soy and other crops for fodder production. ‘At the end of the pipe’ this produces the manure problem. But biorefinery will enable Dutch farmers to arrive at a sound business case without any imports, and with a greatly reduced manure production.

Local feedstock to be competitive with cheap imports

Imported feedstock is cheaper than home-grown proteins and biofuels. The biobased economy will change that, because biorefinery will allow it to close the loop in a circular economy, even while retaining the large livestock population, and grow all fodder in the region. Decisive for this change is that nowadays agricultural side streams that had little or no value five years ago, can now be processed into valuable products. The revenues from these side streams now facilitate a business case in which locally produced fodder is competitive with imported crops.

Biorefinery adds value

A team of researchers from Wageningen UR, Haskoning DHV and CC Advies headed by Johan Sanders now have developed a model that would seem to be a breakthrough (published in Dutch only). They developed the case for the Achterhoek (literally: Back Corner), a picturesque area at the Dutch/German border. Biorefinery is the key. Firstly because using biorefinery, we can deliver the fodder in exactly the correct composition for cow and pig. Secondly, as stated before, side streams (like fibres) now represent an economic value. And thirdly because biorefinery can add value to products formerly discarded, like roadside grass and hulls. The model has been calculated for the Achterhoek, but with some adjustments it might fit other regions as well. The Achterhoek is a relatively sparsely populated area of 1,200 km2 (460 sq. mi.) of which 780 km2 (290 sq. mi.) in use for agricultural purposes. The number of inhabitants is 300,000. Cow livestock numbers 238,000. The area produces approx. 1 million pigs and 3 million poultry annually.

Less manure production at optimal food composition

Less manure production at optimal food composition

At present, food composition for cows and pigs is not optimal. Fodder is not composed in such a way as to produce meat and milk as efficiently as possible, producing the least waste (manure), while retaining animal health and wellbeing. Firstly, animals are fed too much phosphorus, which ends up in phosphate in manure. Moreover, they do not get their proteins (essential amino acids) in the optimal composition, as a result of which they have to eat too much, resulting in an excess of nitrogen in manure. That in turn produces higher nitrate levels in ground water, and enlarged emissions of ammonia and nitrous oxide. Biorefinery can help to address both problems, in particular by a more precise dosage of proteins.

No more need for feed concentrates

No more need for feed concentrates

Biorefinery would enable fodder industry to perform even better. Fibres form a major part of the yield of grass and maize; in their natural state, they cannot be well digested. But if these fibres are separated and ‘pre-treated’, they are better digestible and therefore the animal needs less food. This reduces manure production as well. This is quite effective: in this scheme, cows do not need any feed concentrates any more. Therefore, biorefinery enhances the efficiency of meat production while retaining the animal’s level of wellbeing.

Better protein distribution

Protein availability is crucial. Fodder industry uses much soy meal and other side products of (vegetal) oil producing industries, precisely because of their high amount of proteins and essential amino acids. But we might just as well feed pigs with proteins from grass, their composition is equally good. Grass however we feed to the cows, even though in proportion it contains too much proteins. Therefore, this cycle results in a number of problems: an excess of nitrogen in cow manure (resulting in ammonia etc. emissions), and soy imports to feed pigs (resulting in an excess of manure production). And moreover, proteins are not used efficiently: the cycle has a low food efficiency. Here, economy and ecology point into the same direction.

More efficient use of maize

More efficient use of maize

Maize (and wheat) refinery is technologically less advanced than grass refinery. In course of time, maize refinery might play an important additional role in the new cycle: because this would produce starch from maize that would be excellent pig feed, whereas at present farmers often ensilage maize in order to feed it to cows at a later stage. This efficient use of maize (and the availability of proteins from grass) will allow pig farmers to feed their animals exclusively on locally produced food.

Exchange of crops

The entire circular system boils down to an intricate exchange. We will separate the amount of proteins and amino acids in grass that cannot be incorporated by the cow, and feed it to the pigs. Parallel to that, we increase digestibility of grass fibres for the cow, which results in a lower intake of maize starch, a fraction we may subsequently feed to the pigs. In this way, pig fodder may be produced to a much larger extent from locally grown crops. The entire process will produce not only meat and milk, but biogas and ethanol as well, which we could either use for process heat production, or sell on the market.

Higher productivity

For the circular business case, higher productivity of the land is just as essential as fodder optimisation. Because we can refine grass and feed high-quality grass proteins to pigs, there is a need for more grass production now. So far, this need did not exist because there was enough grass to feed to the cows. Higher productivity in growing grass also has the consequence of higher production of grass fibres, that can be fed to cows resulting in less demand for maize starch. Can we arrive at this higher productivity? The answer is: yes, but we would have to change European manure regulation in order to facilitate that. Manure regulation should be built upon the idea of constraining the net excess of nitrogen that remains on the land. Building upon that foundation, meadows in the Achterhoek could be fertilised better, resulting in a higher productivity, while safeguarding groundwater quality at the same time. Without such an adaptation of manure regulation, the Achterhoek would not be able to become autarkic in fodder.

Towards more local employment

The execution of these ideas would lead to the creation of new jobs. Maize refinery will have to be done in small factories, grass refinery can even be done in mobile equipment that the farmers could host temporarily. Such small-scale installations will have the advantage that minerals from the yield, insofar they are not required for fodder, may be returned to the land right away.

Win-win-win situation

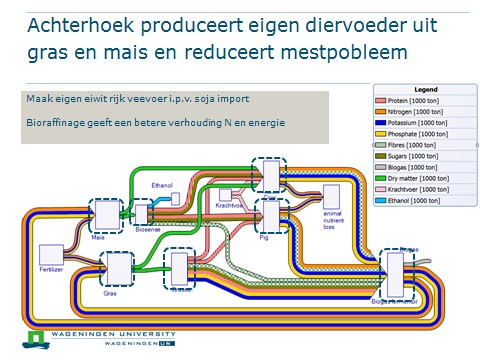

But execution of these ideas might also require new forms of cooperation among a large number of participants. Farmers raising cattle and pigs will have to cooperate, and these in turn with producers of maize and grass, and with fodder producers. The flow process diagram shows the intricate relationships between partners in such a regionally optimised economy. The idea is to arrive at a win-win-win situation, in which farmers profit from a better return on their crops, and from reduced spending on manure treatment. That will have to make up for the difference in feedstock costs between locally produced fodder, and fodder on the basis of imported soy. If that scheme would work, we will only get to know if sufficient stakeholders are willing to participate in the experiment, and would succeed in funding the program as well.

We could also simply eat less meat, which would be even more beneficial for both the environment and our health. What a pity that this major issue is not pointed out in the article.